The Hanford site faces intricate challenges in disposing of the approximately 56 million gallons of radioactive and chemical tank waste. The Department of Energy Office of Environmental Management (DOE-EM) recognizes it as one of the most complex tasks within its nuclear complex. The tank waste treatment mission is also the largest single cost driver at Hanford, with current estimated lifecycle costs of between $199 and $496 billion.

The current tank waste treatment strategy involves separating the waste from Hanford’s 177 large tanks into high-level waste (HLW) and low-activity waste (LAW) streams for processing. The Waste Treatment Plant (WTP) will blend all the HLW and approximately half of the LAW into a solid glass form through a process called vitrification. The vitrified LAW will permanently be stored at the Hanford Site, while the HLW is destined for the nation’s deep geological repository. The approach for treatment and long-term storage of the 15-20 million gallons of remaining LAW, termed Supplemental LAW (SLAW), remains undecided.

In response to this uncertainty, DOE has launched the Test Bed Initiative Phase II (TBI) 2,000-gallon Demonstration Project. The demonstration’s core objective is to establish the feasibility of alternative methods for treating Hanford’s SLAW, specifically grouting (rather than vitrifying) the tank waste, and permanently storing it at commercial disposal facilities outside of Washington state.

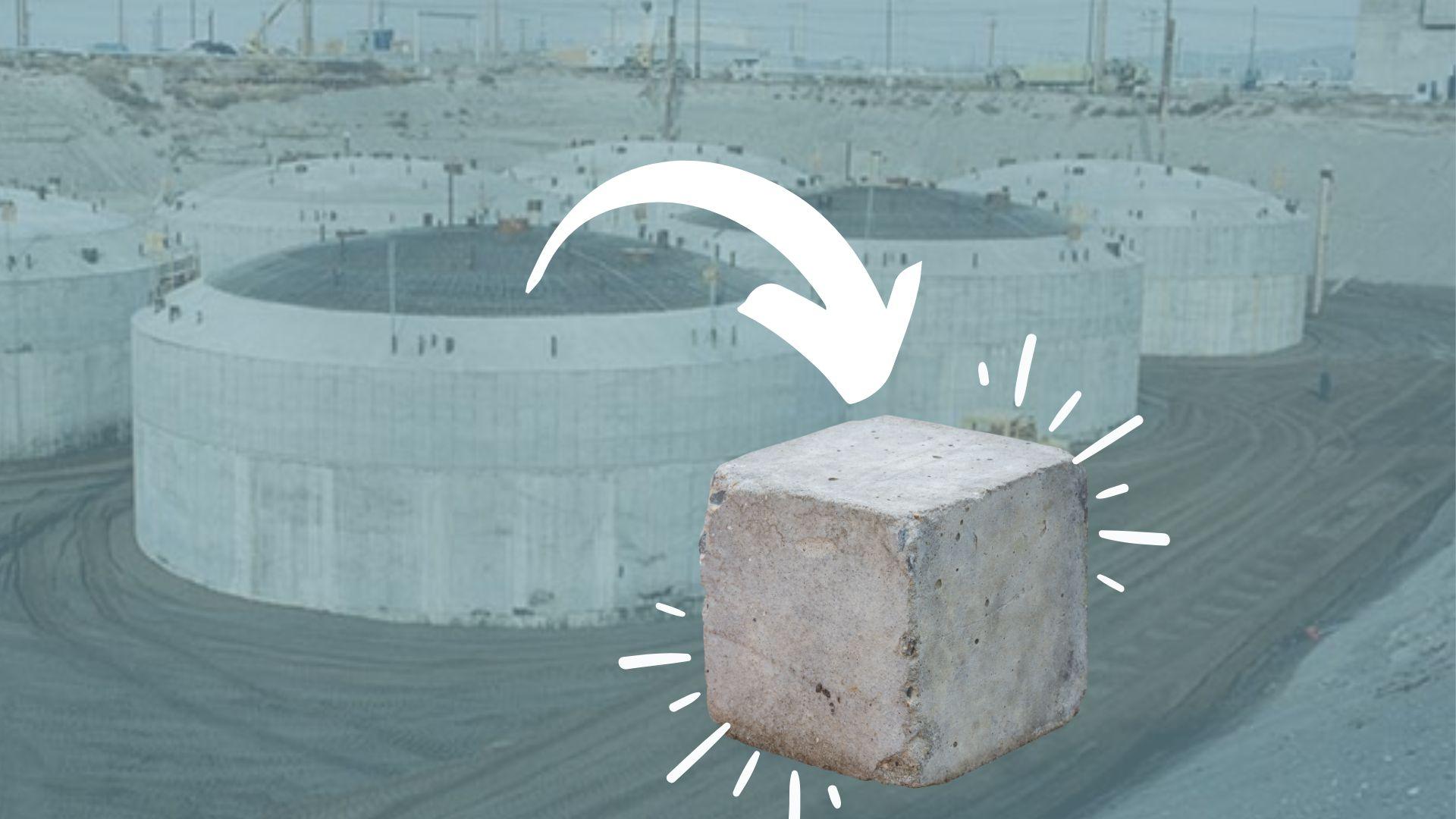

Grouting involves blending the low-activity tank waste with an engineered concrete-like material, which solidifies and immobilizes the waste material. GAO has estimated that grouting supplemental low-activity tank waste could save up to $95 billion[1] and significantly reduce the total amount of time[2] to treat Hanford’s low-activity waste. This involves retrieving and treating LAW using established processes and commercial facilities, then converting it into a solid form for disposal at licensed facilities Waste Control Specialists LLC (WCS) in Texas or Utah.

Initiated in 2016, the first phase of the demonstration served multiple purposes, including authenticating waste treatment methods, guiding tank closures, and ensuring alignment with regulatory standards. The initiative aims to establish the viability of waste treatment strategies before progressing to the design of larger-scale pretreatment facilities.

Building upon the successful 3-gallon first phase, this second phase of the demonstration will be scaled up, to include 2,000-gallon of low activity waste and showcase the ability to safely ship the waste to l Texas and Utah, without affecting the ongoing Waste Treatment and Immobilization Plant (WTP) project.

The task of managing and disposing of tank waste at the Hanford site is undeniably complex, time-consuming, and expensive. This method not only provides potential cost efficiencies but could also accelerate the waste treatment process and accelerate removal of waste from Hanford’s aging tanks.

Looking ahead, the insights gained from this demonstration will provide valuable information to inform future decisions regarding Hanford tank waste treatment and storage.

[1] Hanford Cleanup: Alternative Approaches Could Save Tens of Billions of Dollars | U.S. GAO