The signature radioactive blueish / green glow. We’ve all seen it in movies, and if you ever have the opportunity to see it in person, it’s eerily fascinating. But when tank waste is treated using a process called vitrification (turning waste into a glass like substance), does it still glow?

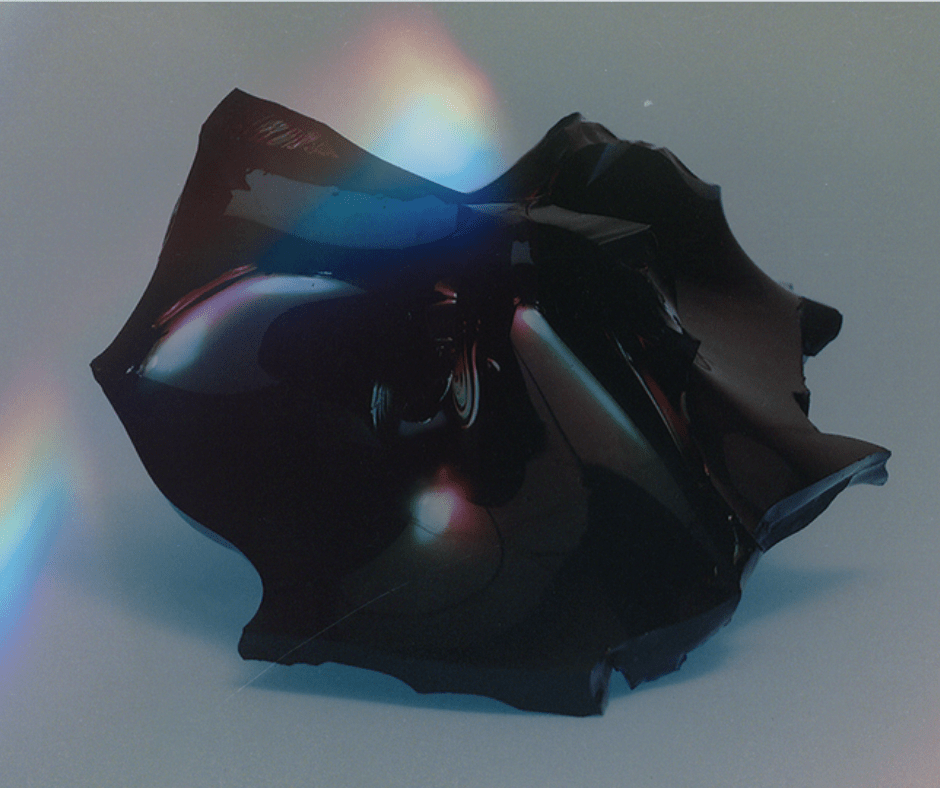

The answer is disappointing, because, no, it doesn’t glow. In fact, it’s a hardened silky black glass like substance. But even though it doesn’t glow, the journey from tank to glass is equally intriguing.

To clarify, the waste that is being vitrified doesn’t glow either. In fact, some of it looks like peanut butter, and is about the same consistency too—but it’s not something to eat, or even get close to. The waste that is being turned into a glass-like material originates from the 177 underground tanks that reside on the Hanford Site. Inside, they contain a mix of radioactive and chemical waste from several decades of plutonium production, 56 million gallons of it to be exact.

And to make matters worse, some of them are leaking. These tanks were intended to serve as interim storage, and now most are beyond their design life. Over the past few decades, there has been a continuous effort to both evaporate excess liquids out of the tanks and transfer waste from single-shell tanks to safer double-shell tanks at Hanford. However, these double-shell tanks are just a temporary fix until the waste can be sent to the Waste Treatment and Immobilization Plant (WTP).

Once WTP is operational it will convert the waste, which can be in liquid form, sludge (like peanut butter), or solid (saltcake) to glass—well, a glass-like material. While this hunk of silky black rock is still radioactive, the risk of seepage and subsequent contamination to air, water and soil is minimized. This process is called vitrification, and it is achieved by mixing waste with glass-forming materials (frit beads), exposing it to 2,100 degrees Fahrenheit in melters, and then pouring the molten material into stainless steel canisters to cool and solidify, ensuring long-term stability for permanent storage.

Ultimately, WTP will vitrify two tank waste streams: high-level waste (HLW) and low-activity waste (LAW). The HLW Facility is in the design, engineering, and construction phase, while the LAW Facility has begun startup and commissioning. This summer marked the first phase of the LAW startup effort, where the first of the two melters was heated up and then began testing with glass-forming materials. In late October, a significant milestone was reached when they began pouring the first test batch of molten glass.

Next, the second of the two melters in the LAW Facility is scheduled for startup in December, benefiting from the knowledge gained during the initial melter’s activation. Cold commissioning with simulated nonradioactive waste is planned to begin in 2024, with hot commissioning, involving actual waste, set to commence in 2025.

As we eagerly anticipate the completion of the Vit Plant’s full capabilities in 2025, the symbolic pouring of the first test glass not only marks a milestone but embodies two decades of both commitment and innovative resilience. This significant achievement, reminiscent of the historic live test of the B Reactor, connects us to a time when engineers faced the uncertainties of its inaugural day with grit, working tirelessly to revive the reactor’s chain reaction. In the ongoing narrative of the Vit Plant, a two-decade journey filled with both setbacks and breakthroughs, the challenges overcome and the melter’s triumphant ascent to the 2100 degrees Fahrenheit mark in July mirror the determination and resourceful spirit that shaped the legacy of the B Reactor.

Beyond the technical victories, this shared history is our hometown badge of honor to the sheer determination of those who’ve gotten down to work and the sharp thinking that’s been the Hanford way, both then and now. As we wade through the twists and turns of nuclear waste, it’s this joint gumption that steers us toward a future where we’re not just tidying up yesterday’s mess but setting the stage for a tomorrow that’s cleaner, safer, and unmistakably ours.